Nav produktu

DUDEK - SNAKE 3

New

INFORMATION FROM MANUFACTURER WEBSITE

The Snake 3 is a challenging slalom wing for top competitors. Very fast and dynamic turns with exceptional resistance to collapses.

The design and testing process lasted a record 5 years. It took so much time and effort to meet the design goals while keeping the self-imposed principle of “no compromises”.

During this time, Snake 3 was extensively tested by the world’s best slalom pilots. They achieved excellent results, often winning the PF1 and PL1 classes.

The Snake 3 is recommended for pilots already familiar with at least DriftAir-class, or more demanding wings. Experienced pilots will appreciate the Snake 3 as an advanced and precise tool to help them win competitions.

Construction

Snake 3 is structurally derived from DriftAir, but its parameters are similar to its predecessor – Snake XX. Here are the most important new design elements:

- LE3D on the leading edge

- new aerodynamic profile

- modified aspect ratio

- new risers with greater range of speed system operation

- modified rigging

- optimization of the attachment points distribution (fixing suspension lines to the canopy)

- change of attachment points for the brake lines

- Leading Edge 3D system enables a better real representation of the aerodynamic profile and reduces the amount of wrinkles on the fabric in the most important place in terms of lift and air resistance.

Rigging modifications increase trailing edge stability at high speeds. These elements, together with a carefully selected profile and aspect ratio, create a coherent structure meeting all the design goals.

More construction details

Shark-nose (SN) on the leading edge takes care of better aerodynamics of this part of the canopy, as well as higher inner pressure at wide range of the attack angles (meaning airspeed).

The leading edge is stiffened with synthetic rods of the FET (Flexi Edge Technology), distinctly improving launch quality and guarding against collapses at high speeds.

In addition Leading Edge 3D system enables a better real representation of the aerodynamic profile and reduces the amount of wrinkles on the fabric in the most important place in terms of lift and air resistance.

The design features also other effective methods of canopy loads distribution, mediated by most modern sewing technologies.

Four rows of suspension lines are joined at the risers, equipped with compact yet very efficient tools like trimmers, speed and Power Attack (PA) system.

Steering system of the DriftAir is our well known, original solution of 2D steering, this time with new adjustable CHR handle, combining features of both the TCT and TST (Tip Steering Toggle).

As per our standard, the risers are equipped with three optional positions for the steering pulleys and magnets to choose from. Thanks to all these features, steering operation is straightforward and intuitive.

Obviously, in some powerpack/canopy configurations considerable amount of torque can appear. To counter this, there is proven in our Warp an automatic TEA system (Torque Effect Adjuster). It works on its own after placing the line on proper side, depending on the torque direction.

Due to the small number of lines, they were carefully selected to obtain the lowest possible air resistance, while ensuring high strength and resistance to stretching. The upper layer lines, attached to the wing’s suspension points are unsheathed, in the lower layers we use regular sheathed lines.

Snake 3 is manufactured entirely in Europe, at our Polish plant, so that we have total control over its sophisticated production process (using among else the advanced LT (Laser Technology) cutting.

Design solutions, technologies and other functionalities are listed below in the Technologies section.

TECHNICAL DATA

Technical details

| Snake 3 – sizes | 14 | 15 | 16 | 17 | 18 | 20 | 22 |

| Approval – ULM identification | pending | pending | pending | pending | pending | pending | pending |

| Number of cells | 60 | ||||||

| Surface area (flat) [m2] | 14.00 | 15.00 | 16.00 | 17.00 | 18.00 | 20.00 | 22.00 |

| Surface area (projected) [m2] | 12.16 | 13.02 | 13.89 | 14.76 | 15.63 | 17.36 | 19.1 |

| Span (flat) [m] | 8,97 | 9.28 | 9.59 | 9.88 | 10.17 | 10.72 | 11.3 |

| Span (projected) [m] | 7.35 | 7.61 | 7.86 | 8.1 | 8.33 | 8.78 | 9.21 |

| Aspect Ratio (flat) | 5.80 | ||||||

| Aspect Ratio (projected) | 4.44 | ||||||

| Speed* [km/h] | min = 30 ; trim = 44-62 ; max = 77 (+/- 3 km/h)* | ||||||

| Distance pilot to wing [m] | 5.23 | 5.41 | 5.59 | 5.76 | 5.93 | 6.25 | 6.78 |

| Total line lenght [m] | 244,1 | 257.27 | 266.14 | 274.73 | 283.08 | 299.10 | 308.95 |

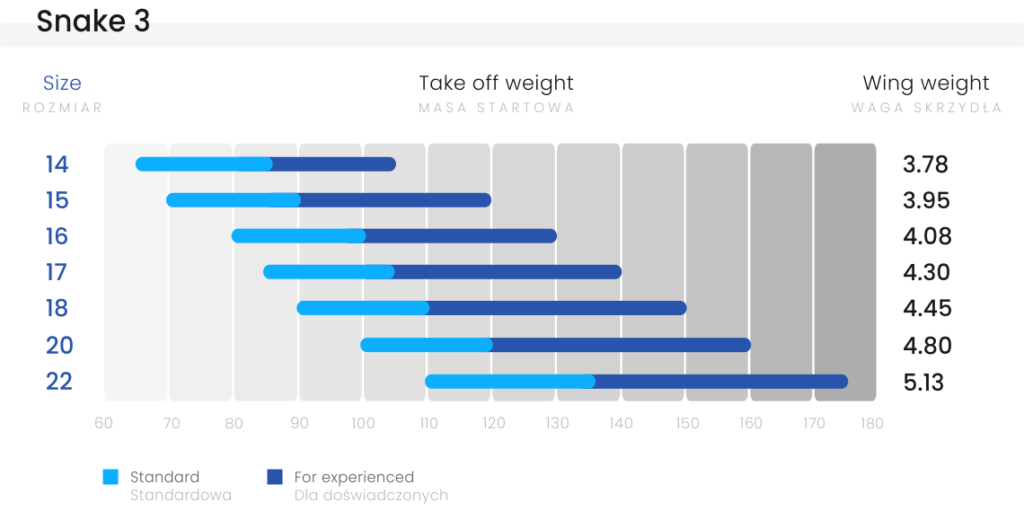

| Total take-off weight** [kg] | 65 – 85** | 70 – 90** | 80 – 100** | 90 – 110** | 100 – 120** | 110 – 135** | 120 – 150** |

| Max take-off weight – for experienced*** [kg] | 115*** | 120*** | 130*** | 140*** | 150*** | 160*** | 175*** |

| Distance betwen risers [cm] | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Weight [kg] | 3.78 | 3.95 | 4.08 | 4.30 | 4.45 | 4.80 | 5.13 |

| Lines | A-8000U: 050; 070; 090; 130; 190 / Technora: 140 & 190 & 280 / Dyneema: 350 | ||||||

| Fabric | Porcher Sport 38 g/m2; Dominico tex 34 g/m2; Porcher Hard 40 g/m2; SR Scrim, SR Laminate 180 g/m2 | ||||||

* Speeds are given as estimated for the middle wing size and the middle of its weight range. These speeds can vary within +/- 3 km / h depending on the size, take-off weight and additional factors such as air pressure and temperature.

** The basic rule is to choose the size of the wing so that the take-off weight is in the middle of the weight range. Less weight on the wing (lower range take-off weight) can be considered for foot take-off, when flying in calmer conditions, or when we want to improve economy. More experienced pilots who want to fly dynamically, have higher speed and fly in more demanding wind conditions can consider greater wing loading (take-off weight in the upper range). This is a common option among trike users.

*** Note – the canopy significantly changes its behavior with increasing wing loading. The greater the loads, the greater skill and concentration of the pilot are required.